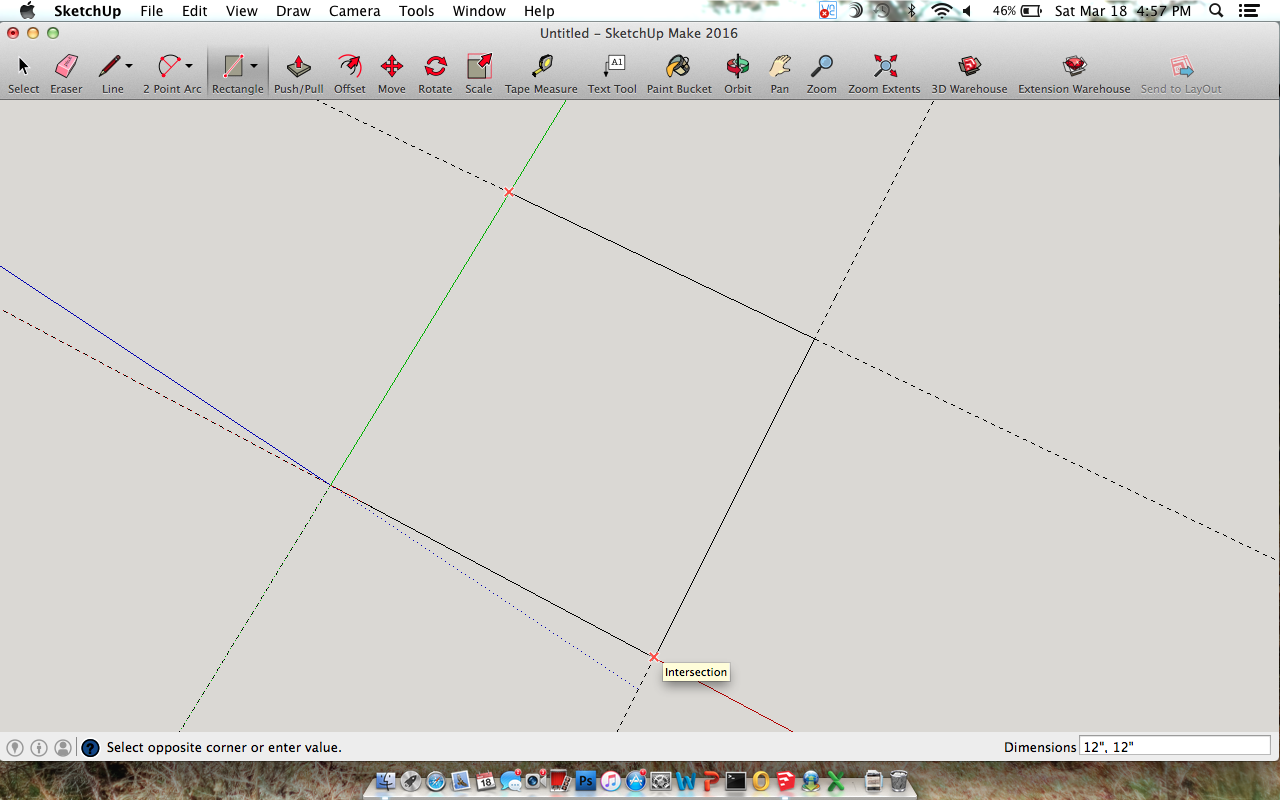

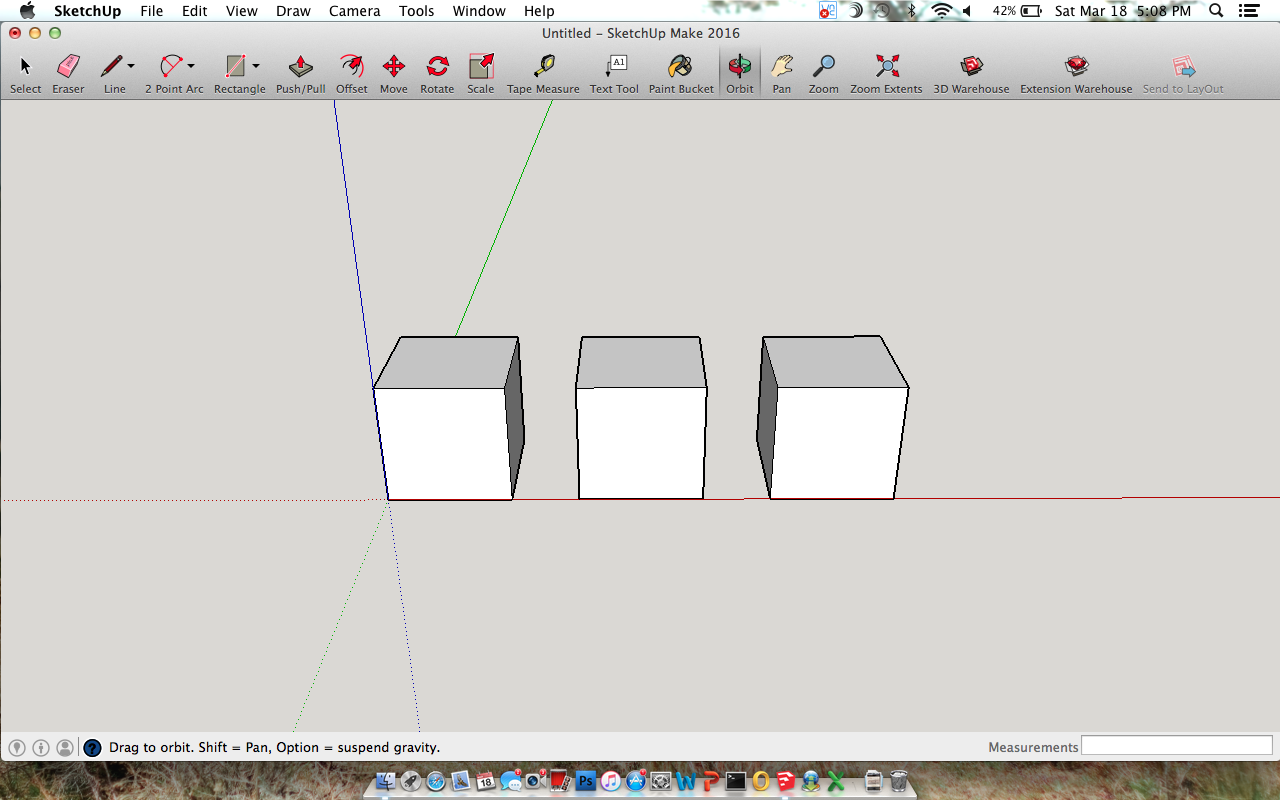

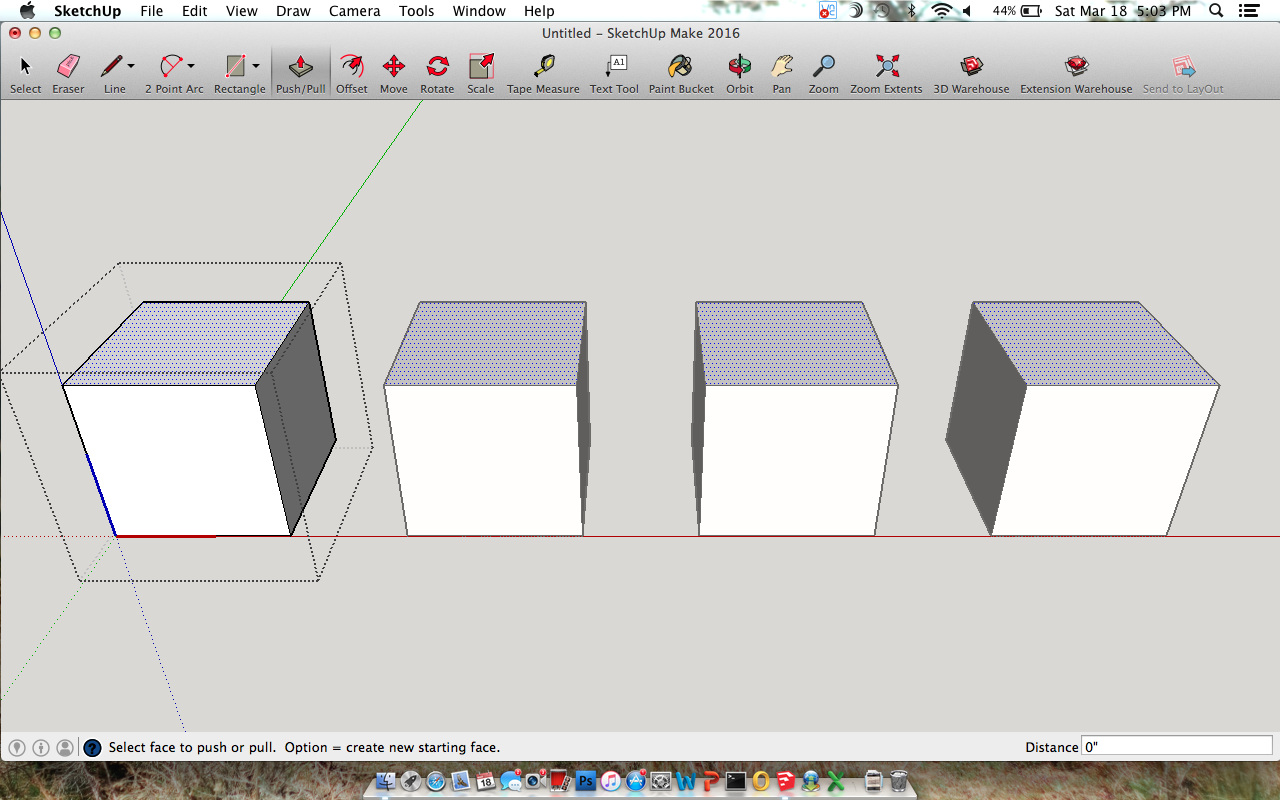

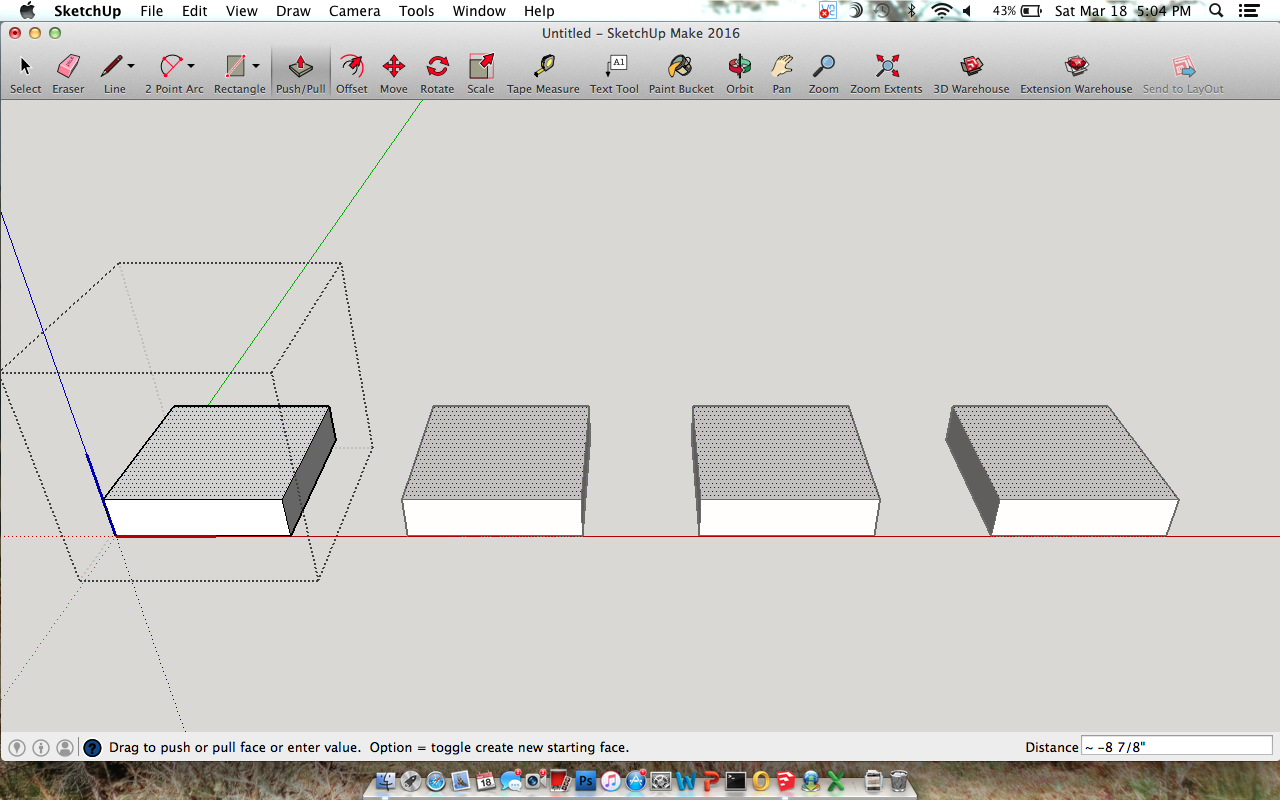

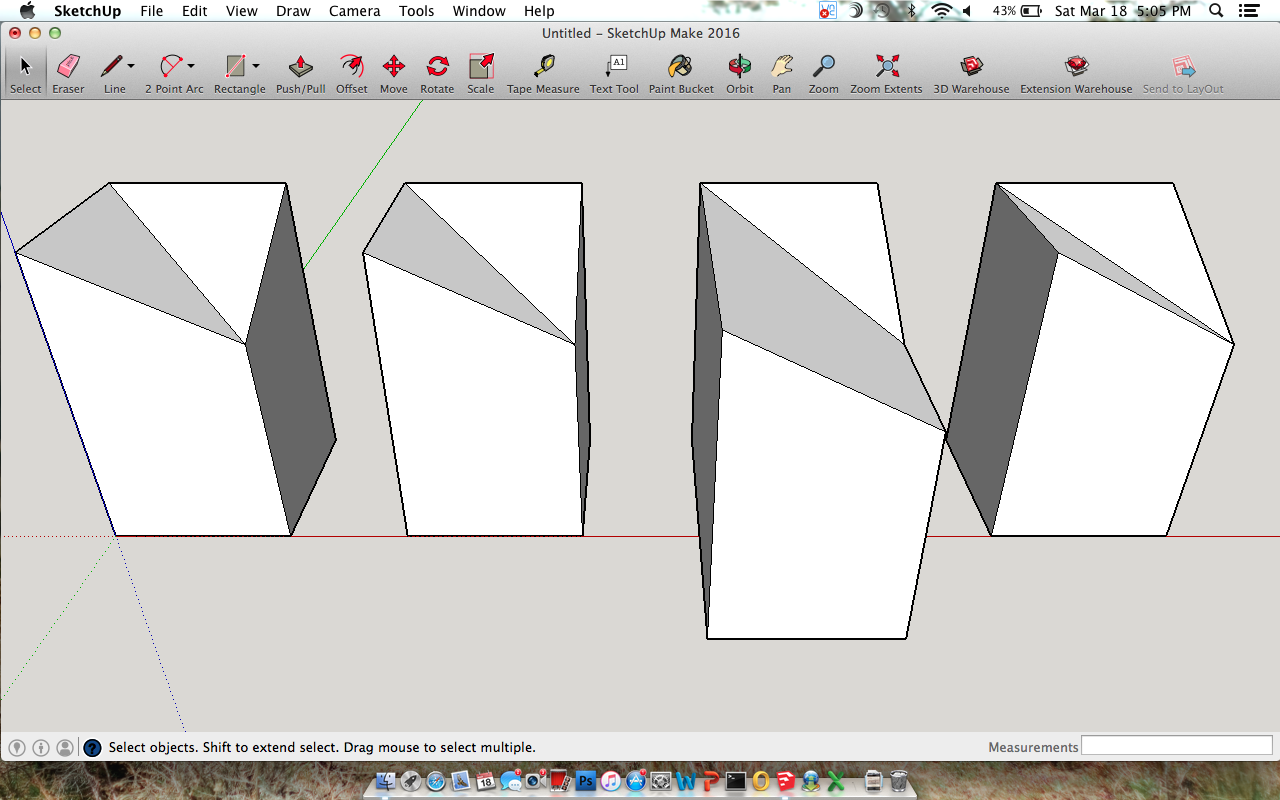

I think it is always a good idea to look back on your previous work to see how far you have come and what you can improve on. 2016 is when Howard Built LLC was officially launched, and I had multiple memorable projects throughout the year. At the time, I was working out of a large quonset hut just outside of Boise in Garden City, Idaho. There are many great memories of working late into the night to get orders fulfilled and pieces completed. Now I am thankful to say I have a home with a shop right on the property.

Here are just a few of the projects and process photos from my time in that space.